Grab and backhoe dredgers

Next to the use of TSHD also grab and backhoe dredgers will be used. A grab and backhoe dredger use a ship with backhoe and grabbers on top of the ship. These dredgers grab area, depending on the volume of the backhoe or grabber, of mud and sand and place in into bulk carriers that ship the soil towards the dumping area.

Backhoe dredger

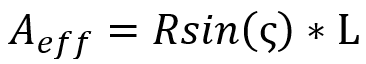

A backhoe dredge is a stationary tool that is on top of a moveable pontoon. With a backhoe dredger the pontoon is moved in direction of the dredger. During the dredging part the pontoon is lifted partly out of the water to create anchoring. For the dredgers used in the TUAS mega port a 3-point anchor system is used1. This system is used so that the direction of the pontoon can be change much faster and easier. Moreover, the dredger is now less sensible for waves. The backhoe dredger that is used for the construction of the port is a PC5500 hydraulic excavator of KOMATSU2. This dredger has a maximum digging depth of 19 meters and a reach of 20 meters. For the backhoe an import parameter is the effective dredging area. This is depended on the swing angle and the forward step of the backhoe. The forward step of the backhoe is determined by the boom and stick length. For the PC5500 the boom length 11 meters and the stick length are 5.1 meters. Because the pontoon has 3 anchor points the swing angle is restricted, which means that the angles larger than 60 degree are less effective. The effective dredging area can then be found with the formula3:

The forward step is 11 meters + 5.1 meters= 16.1 meters. The effective width of the dredger is: 16.1*2=32.2 meters. The angle that of the swinging is so the largest angle is 60 degrees. This means that the effective area will be: Aeff = 32.2*sin(60) * 16.1 – 32.2*sin(60) * 11 = 142.2 m2 This means that the step the pontoon can make is. 5.1 meters.

After the effective area the forward step size also needs to be determined. The step is depended on the width of the bucket, for a PC5500 the standard with is 4.38 meters and the bucket forward position or in other words the step. Because the volume of the bucket is constant a small step a will result in a larger width that is dredged and reversed. The volume of the bucket is 24 m^3 for mud bucket and 17.5 m^3 for heavy duty bucket. The width of a bucket is around the 4.38 meters. This means that the layer thickness for the different bucket sizes can be calculated3.

With the provided calculator the width of the bucket can be changed to see how the layer thickness changes.

With the step size and layer thickness known the production capacity of the backhoe dredger can be determined. To determine the capacity the excavating time of the dredger must be known. For most backhoe dredgers the cycle to dredge the soil is. Digging, lifting the soil and swinging above the bulk carrier, dumping the soil in the bulk carrier, swinging back and lowering the bucket to the dredging location and position the bucket at the right location. The cycle time is around the 20 to 40 seconds. This means that the excavating time per bucket is around the 30 seconds.

From the formula the production capacity for the mud bucket and heavy-duty bucket where found and are Qs, mud bucket=0.8 m3/s and Qs, H.D. bucket= 0.6 m3/s.

With this calculator the step size, thickness of the layer and the width of the bucket can be changed to see the production capacity change. Here the formula for the production capacity is:

Layout

The main layout of backhoe dredger can be seen in the picture. From this picture it can be seen the crane is on the front side of the pontoon and that the engine room is located towards the middle of the pontoon. During the project a bulk carrier will be placed next to the dredger so the dredged soil can be placed in the bulk carrier and can be transported to the location where the material will be dumped.

Grab and clamshell dredger

The grab and clamshell dredger are more commonly used in the world. The pontoon is the same as for a backhoe dredger and is kept in place the same way. The grabbing capacity of a clamshell is larger than the capacity of a backhoe. The grab can be opened and closed with the use of hydraulic cylinders.

The grab dredger is used for bulk dredging and at depth larger than 25 meters4. This means that for the Tuas terminal the grab dredger is not used because the depth of the surrounding area is around the 20 meters.

Other Construction Aspects

Trailing Suction Hopper Dredgers

One of the vessels used to reclaim the land for the construction of the port. The Queen of The Netherlands is Boskalis´ biggest Trailing Suction Hopper Dredger. For more details click here.

Caissons

The caissons are one of many aspects which make this construction process unique. The caissons are made in a huge factory that has been set up on the project site. For more details click here.

Soil Improvement

The soil at the project site consists mainly of clay. Therefore soil improvements are necessary to create a stable foundation for the port. For more details click here.